| Wright Aeronautical Engines 1937 - USA | |

|---|---|

| Home Page | Engine Index |

| |

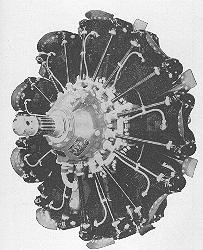

| This version of the nine cylinder G Cyclone R-1820-G2, has a rating of 1,000 horsepower for take-off. | |

|

Wright Aeronautical Corporation, Paterson, N. J., the aircraft engine manufacturing division of

the Curtiss-Wright Corporation, announced that during the first six months of 1936 more than

1,300 of their Wright Whirlwinds and Cyclones had been sold to aircraft manufacturers, air line

operating companies and military services throughout the world. These orders represented the

sale of more than 1,077,000 hp. More than 1,000 of the 1,300 engines sold were of the Wright

Cyclone type, used extensively in large air transports and military aircraft. The orders for 1,000

Cyclones were believed to represent a new peace time sales record for high-powered aircraft

engines over a six months period. Of this number over 700 were Cyclones of the 1,000 hp type

which was released for domestic and commercial sale during the summer. Designated as the

Wright Series G Cyclone, the 1,000 hp model was introduced to the commercial market on the

10th anniversary of the Cyclone Series. To date the Wright Aeronautical Corporation has

produced over 25,000 engines of which over 11,000 were of the radial aircooled type.

Over 600 of the 1,000 hp Cyclones on order were scheduled for delivery to the U. S. Army for installation in the new Douglas B-18 twin engine and Boeing B-17 four-engine bombers. Others were used to power the Douglas DC-3 DST transports placed in service by American Airlines. During 1936 the Wright Aeronautical Corporation produced five distinct series of aircraft engines. They were the Wright Cyclones F and F-50 and the Wright Cyclone G Series high-powered, nine cylinder radial aircooled engines; the single-row Whirlwind series of five, seven and nine cylinders; the 14 cylinder Wright double-row Whirlwind Series, and the Curtiss Conquerors. The Wright G Cyclone Series represented the latest aircooled aircraft engine developed by the company. Although of the same displacement (1,820 cubic inches) as the F and the F-50, the G Series engines incorporated many refinements and improvements in design principal. Among them was a new cylinder which has a cooling fin area of 2,800 square inches against 1,000 square inches in other Cyclone models. Advancement in foundry technique in the Wright Aeronautical foundry, made possible the casting of cooling fins on the G cylinder head as closely spaced as the teeth on a comb and nearly two inches in depth over the combustion chamber. Cylinder barrels were of Nitralloy steel, nitrided to obtain a cylinder bore with a surface with three times the wear resistance of ordinary heat-treated cylinder barrels. Five large nitriding furnaces were installed to accommodate the daily output of Cyclone G cylinders. More accurate fuel control and the improved cylinder heads on the G Cyclone engine permitted a rating of 1,000 hp at take-off with a weight in certain models of 1.07 pounds per horsepower and fuel consumption of .43 pounds per horsepower at cruising speed. Other features of the design and construction of the G Series Cyclones were automatic lubrication of the valve gear from a built-in system devoid of all external lines or tubes, mechanism for the operation of two-position hydro-control and constant speed propellers, an accessory section provided with the driving mechanism necessary to meet all of the requirements of modern military and civil transport service, the dynamic damper counterweight which counteracts torsional vibration at all crankshaft speeds and removes all restrictions in the operating range, full pressure baffling of the cylinders, improved oil seals and refinements in the supercharger and induction systems to increase altitude performance. The G Cyclone was produced in four geared models and their direct drive counterparts. These were the Cyclone GR-1820-G1 rated at 940 hp for take-off, 825 hp at sea level, and 850 hp at 3,000 feet; the Cyclone GR-1820-G2 rated at 1,000 hp for takeoff, 810 hp at sea level, and 850 hp at 5,500 feet; the Cyclone GR-1820-G3 rated at 875 hp for take-off, and 840 hp at 8,700 feet; and the Cyclone GR-1820-G6 rated at 820 hp for take-off and 815 hp at 10,500 feet. The various G Cyclone models differ only with respect to the amount of supercharging applied. The G-1 has a blower gear ratio of 5.95 to 1; the G-2 a blower ratio of 7 to 1; the G-3 a blower ratio of 8.31 to 1 and the G-6 a blower ratio of 8.83 to 1. All the G Series engines are of the nine-cylinder radial aircooled type and have the following characteristics: bore, 6.125 inches; stroke, 6.875 inches; compression ratio, 6.45 to I; diameter, 54 1/4 inches; length, 43 1/4 inches; dry weight (geared) 1,163 pounds, (direct drive) 1,068 pounds. The F-50 Series Cyclone was produced in four direct drive models and their geared counterparts. These were the Cyclone R-1820-F52 rated at 890 hp. for take-off, 745 hp at sea level, and 775 hp at 5,800 feet; the Cyclone R-1820-F53 rated at 785 hp for take-off, 685 hp at sea level, and 745 hp at 9,600 feet; the Cyclone R-1820-F54 rated at 655 hp for take-off, 605 hp at sea level, and 690 hp at 15,300 feet; and the Cyclone R-1820-F56 rated at 785 hp for take-off, 695 hp at sea level, and 755 hp at 11,300 feet. Like the engines of the G Cyclone Series, the models of the F-50 Series are identical except for the amount of supercharging applied. All are nine-cylinder radial, aircooled engines. The F-52 has a blower gear ratio of 7 to 1; the F-53, a blower gear ratio of 8.31 to 1; the F-54 a blower gear ratio of 10 to 1, and the F-56, a blower gear ratio of 8.83 to 1. Characteristics common to all F-50 models are: bore, 6.125 inches; stroke, 6.875 inches; compression ratio, 6.40 to 1; diameter, 54-1/8 inches; dry weight, (geared) 1,070 pounds, (direct drive) 975 pounds. |

|

|---|

| This seven-cylinder model has ratings of 235, 250, 285 and 320-350 horsepower. |

|

The single-row Whirlwind models of five, seven, and nine cylinders, which have been under

development for over 16 years, were also refined during 1936. The ratings of the series were:

five-cylinder 175 hp.; seven-cylinder 235 hp; 250 hp, 285 hp and 320-350 hp The

nine-cylinder Whirlwinds of 330 hp, 365 hp, and 420-450 hp were characterized as "deluxe

equipped" Whirlwinds due to their many standard and special features. These engines were

provided with automatic valve gear lubrication, a new type of nose exhaust collector ring with

built-in carburetor intake and air heater, dynamic damper counterweight, mechanism for the

operation of the two-position hydro-control propeller, a three-way drive for the operation of

a vacuum pump, a fuel pump, and a constant speed propeller governor, full pressure baffles

provided with blast tubes for the cooling of the accessories and ventilation of the engine

compartment and heating or cooling and ventilation of the cabin of the airplane; two mounting

diameters provided by two sets of mounting lugs, the larger of which, corresponding with that of

the Cyclone, provides greater accessibility in installations where the engine is mounted in rubber;

complete radio shielding for ignition wiring, spark plugs, and magnetos, and the dynamic damper.

Some of these features are also provided in the Whirlwinds of 250 hp, 285 hp, 330 hp and 365 hp. The following specifications are common to all Whirlwinds, parts of which are over 90 per cent interchangeable: bore, 5 inches; stroke, 5.5 inches and diameter, 45 inches. Weights, compression and blower ratios vary with individual models. Development was continued in the higher horsepower categories with the double row Whirlwinds designed for military service. These engines now have ratings as high as 900 hp for take-off and 800 hp at 6,000 feet. The Curtiss Conqueror, a 12 cylinder V-type engine, used by the Army Air Corps for installation in high speed combat planes, was offered as a geared engine rated at 655 hp and 675 hp. The Conqueror is the only liquid-cooled engine built on a production basis in the United States. It may be operated with either water or Prestone as the coolant. The factory and foundry of the Wright Aeronautical Corporation at Paterson, N.J., comprises more than 650,000 square feet of floor space. During 1936 the Wright Company pioneered in the installation of Magnaflux testing equipment for the inspection of steel parts, nitriding equipment and furnaces to provide a super-hard bore in Cyclone cylinder barrels and machinery for the grinding of studs. All steel parts of Wright engines are subjected to the Magna flux test which shows up defects which might not be discernible under microscopes of 10 to 20 diameter enlargement strengths. The Wright installation of Magnaflux equipment, like its installation of nitriding equipment, were the first to be made in this country. During 1936 the Wright Aeronautical Corporation also, set up a modern experimental testing laboratory which is equipped to make endurance tests on engines of outputs up to 2,500 hp. |

© The Aviation History On-Line Museum. 2006 All rights reserved.