| Le Rhône Rotary Engine |

|

||

|---|---|---|---|

| |

|

||

|

|||

|

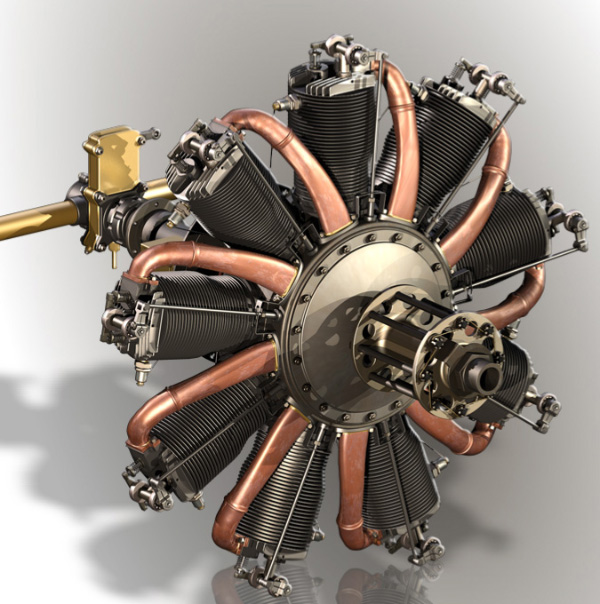

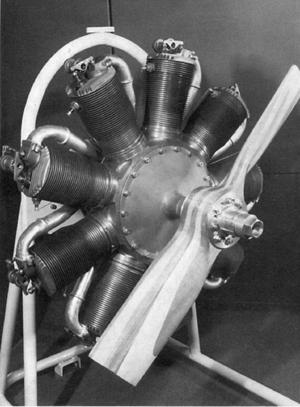

It had a conventional induction system and a remarkable method of connecting the link rods to the master rod. In the Le Rhône, the fuel mixture went first to have an annular chamber at the back of the crankcase and thence, by attractive polished copper pipes, to conventional intake ports and cam-operated valves in the cylinder heads.

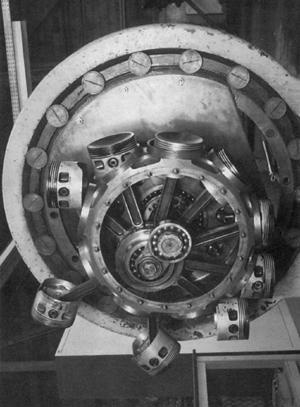

Although remarkable, the Le Rhône used a complicated slipper bearing system. Its master rod had three concentric grooves to take slipper bearings from all the other cylinders. The master rod was a split-type to allow assembly of the connecting rods. The remaining rods carried bronze shoes, shaped to fit in the grooves, at their inner ends. Counting the master rod as no. 1, the shoes of no's. 2, 5, and 8 rode in the outer groove, those of 3, 6, and 9 in the middle groove, and 4 and 7 in the innermost one. |

|||

|

|

||

|

The Le Rhônes employed an unusual method of valve actuation. A single rocker arm, pivoted near its center, was made to operate both the exhaust valve and the intake valve. Pulled down, it opened the intake valve; pushed up, it opened the exhaust. To do this, the rocker had to be actuated by a push-pull rod instead of by the usual pushrod. This in turn, meant that the cam followers had to have a positive action and a system of links and levers to accomplished this. The system worked well enough that some makers used it up to the late twenties, but its use made overlap of valve openings impossible. In an engine designed for high power and speed, the intake valve begins to open before the exhaust valve is quite closed, but on the Le Rhône, the rocker arm must clear the exhaust before it can contact the intake. While this puts a limit on power output, it is not necessarily a fault. As it was, most Le Rhône models produced all the power that their structural strength and cooling arrangements could cope with.

Le Rhône 80-hp models were made under license in the United States by a Pennsylvania firm, Union Switch and Signal. Oberursel made the 110-hp model, supposedly without authorization in Germany. The Oberursel U.R. II was a straight copy of the Le Rhône but the Le Rhône was preferred over the Oberursel due to the superior materials used over the home product. However, there were reports in July, 1918 that there was a shortage of Castor Oil which the rotaries required. A new Voltol-based lubricant was substituted and was blamed for a rash of engine failures on Fokker E.V using the Oberursel U.R. II rotary engine. It has been suggested that without the proper lubricants, the Le Rhône rotary would have been equally failure prone. The largest wartime Le Rhône gave only 130 hp. As rotaries went, they were dependable engines. |

|||

| Specifications: | |||

|---|---|---|---|

| Model | 80 Hp Le Rhône |

110 Hp Le Rhône (Type J) |

Oberursel U.R. II |

Date: | Circa 1916 | Circa 1916 | Circa 1916 |

| Cylinders: | 9 | 9 | 9 |

| Configuration: | Rotary, Air cooled |

Rotary, Air cooled |

Rotary, Air cooled |

| Horsepower: | 80 hp (59 kw) |

113 bhp (84 kw) |

110 hp (82 kw) |

| R.P.M.: | 1,200 rpm | 1,200 rpm | NA |

| Bore & Stroke: | 4.1 in x 5.5 in 105mm x 140mm |

4.4 in x 6.7 in 112mm x 170mm |

4.9 in x 5.9 in 124mm x 150mm |

| Displacement: | NA | 920 in³ | 995 in³/16.3 L |

| Weight: | NA | 330 lbs (149 kg) | NA |

© The Aviation History On-Line Museum.

All rights reserved.

Created June 21, 2001. Updated February 3, 2014.